Enhance your sales planning across short, medium, and long-term horizons. Effectively manage demand based on historical data and other relevant determinants. Utilize a planning platform to efficiently analyze data and lead the forecasting process at any level of aggregation. Execute the demand planning process in an environment where marketing, sales, and planning departments collaboratively establish a "consensus," the best and achievable demand plan. The application workflow is tailored to the specifics of your business, perfectly aligning with your needs and processes.

Prepare your data for use in the forecasting process. Analyze and classify sales history, eliminate disturbances, both known and random, so that the data provided to the forecasting process is of the highest quality.

Optimize your demand forecasting process by ensuring greater data transparency, accelerating decision-making, and optimizing risk management. Apply the best statistical methods and, where necessary, expert knowledge to automate the forecast generation process.

Initiate collaboration with your clients to gather more insights into their future demands and production requirements. Access to the planning platform can be facilitated through user interfaces or automated integrations.

Make supply chain and production decisions based on reliable and real data, utilizing efficient analytical processes.

Develop a procurement plan based on the operational production schedule and conduct supplier analyses to ensure your production is executed with the best material configuration, always just in time. Proactively respond to any disruptions in material availability.

Conduct a flexible medium and short-term planning process, and then translate it into real schedules. Afterward, review the progress of the plan to identify discrepancies and improve planning processes in each subsequent iteration.

Calculate the availability of production resources at individual production nodes based on the production schedule. Optimize and manage in real-time. In the long term, efficiently and transparently coordinate production resources. Precisely schedule staffing availability and supplement with the logistics and transportation resource availability.

Have all your data at your fingertips. By analyzing supplier availability in the context of the production schedule and contractual agreements, you can assess the best collaboration option and ensure the timely delivery of finished goods.

Globally manage inventory across your locations. Analyze both the current situation and variability over time. Always know where each item is needed and where your inventory is located.

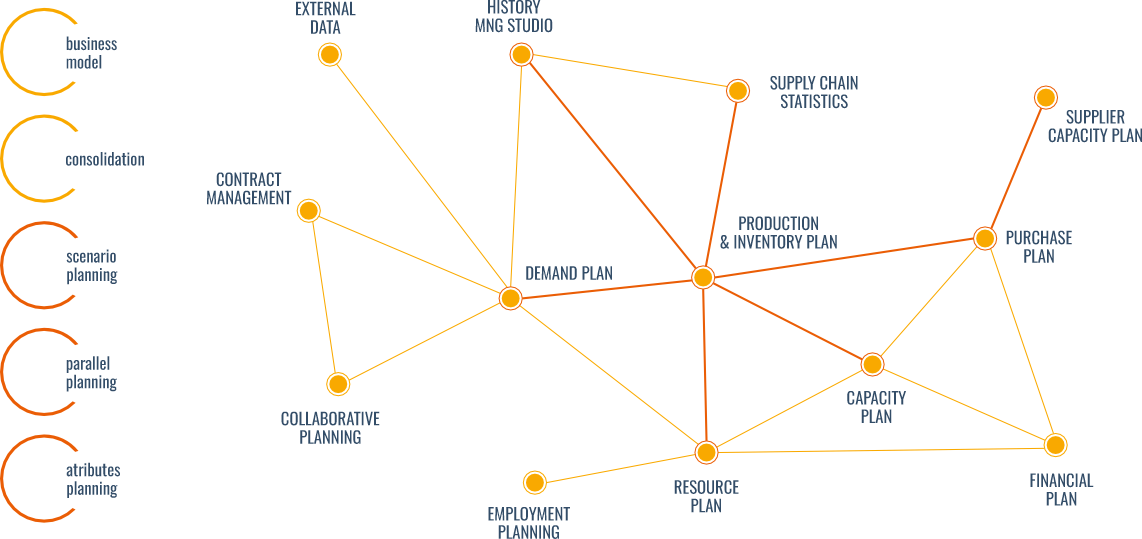

Execute your planning process step by step, conducting successive analyses and implementing processes—from forecasting, through production planning, to procurement planning—enhancing your Sales and Operations Planning (S&OP) processes.

The planning platform serves as a unique hub, consolidating data from various sources, spanning planning processes, sales, supply chain management, and financial data. Make decisions based on real and up-to-date information gathered in one central location.

An innovative approach to the S&OP process is achievable through the utilization of a planning platform, fostering collaboration across departments and enabling swift decision-making based on reliable analyses and user insights.

The BiModal Planning Platform also features modules that can be integrated into a larger framework, seamlessly connecting, supporting, or complementing other solutions and sometimes functioning independentl. Explore these modules to elevate your planning to a higher level!

Stabilize your production and ensure a high level of standardization! Plan in the short term using the leveling concept, a critical element of the Toyota Production System. BiModal Leveling is a unique solution based on the "every part every interval (EPEI)" principle, seamlessly integrated with ERP systems (SAP & IFS).

What if we gather all necessary tasks in one place on the planning platform? Why not! Our module allows task management by associating them with specific modules and available data in the solution. You always know where you stand and what you're working on.

Keep key performance indicators related to your supply chain under control. You choose the indicators. You define your level of sophistication. You customize the content to your needs, yet see a developmental path. Analysis. Dashboards. Insights. Decisions.

How to plan when your production relies on long production runs and exhibits low variability? Effortlessly - with the module of our planning platform designed to accommodate such production characteristics.

Efficient planning in the face of significant production variability is achievable. If your company deals with an extensive list of part numbers, manages very short production runs, or handles numerous variations of a finished product, we have a module specifically designed for your needs.

This website uses cookies to ensure you get the best experience on our website.

Read more about it - privacy policy & cookies policy.

If you are interested in meeting with us,

please fill this form.